Defect marking

WDM offers the possibility to perform and record a machine-readable defect marking from the basic production to the final assembly.

Integration of a surface inspection system as well as corona stations, thickness measurements and other machine conditions.

WDM:

WDM offers the possibility to perform and record a machine-readable defect marking from the basic production to the final assembly.

Integration of a surface inspection system as well as corona stations, thickness measurements and other machine conditions.

WDM:

WDV is installed at the converting lines

The role log generated by WDM with all the

defect information and position details is available.

At the start of the finishing process, the operator is provided with a visualized defect map with position information.

Automatic stop at the defect position for

processing.

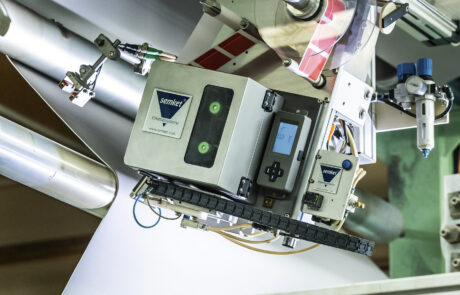

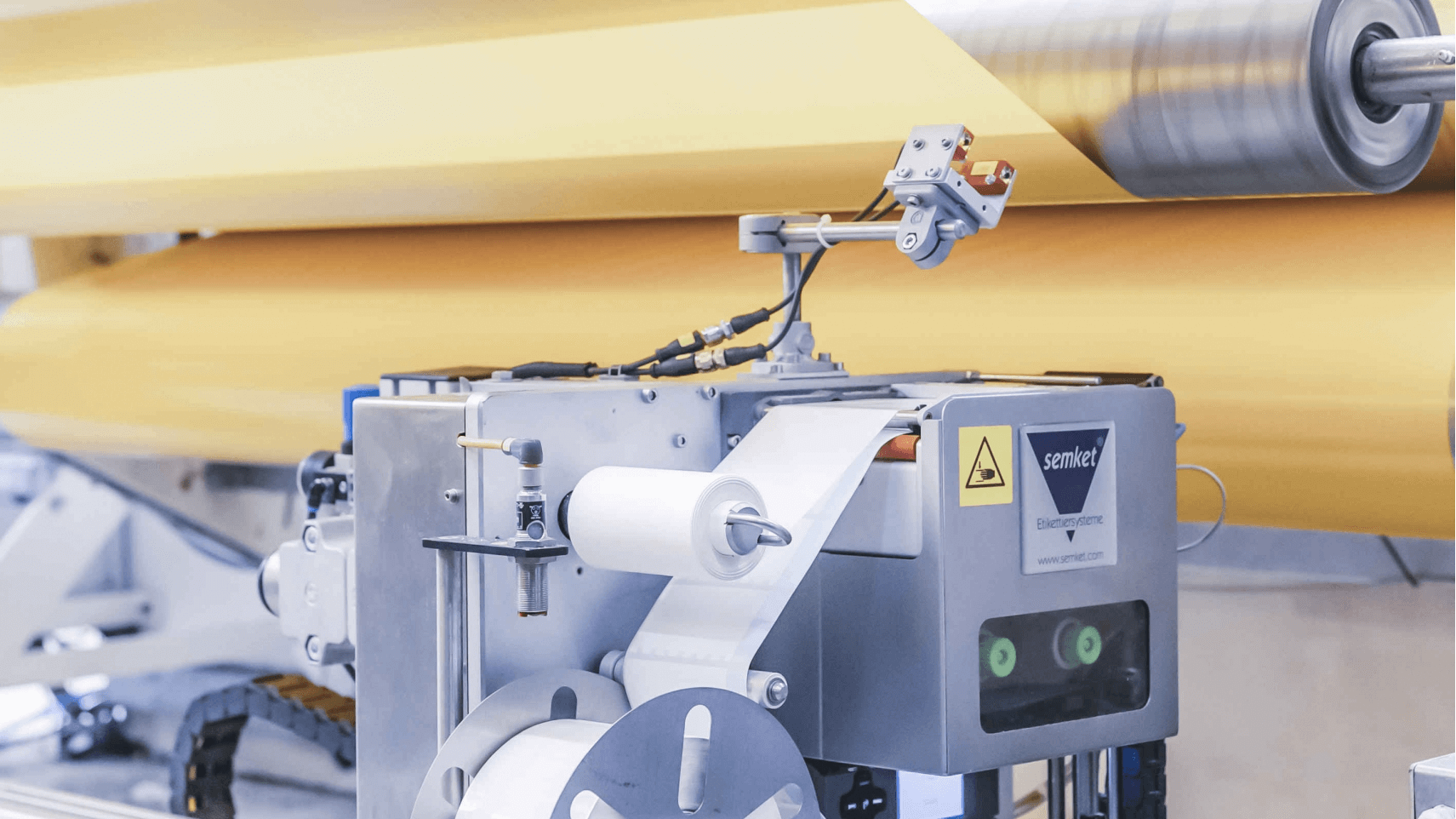

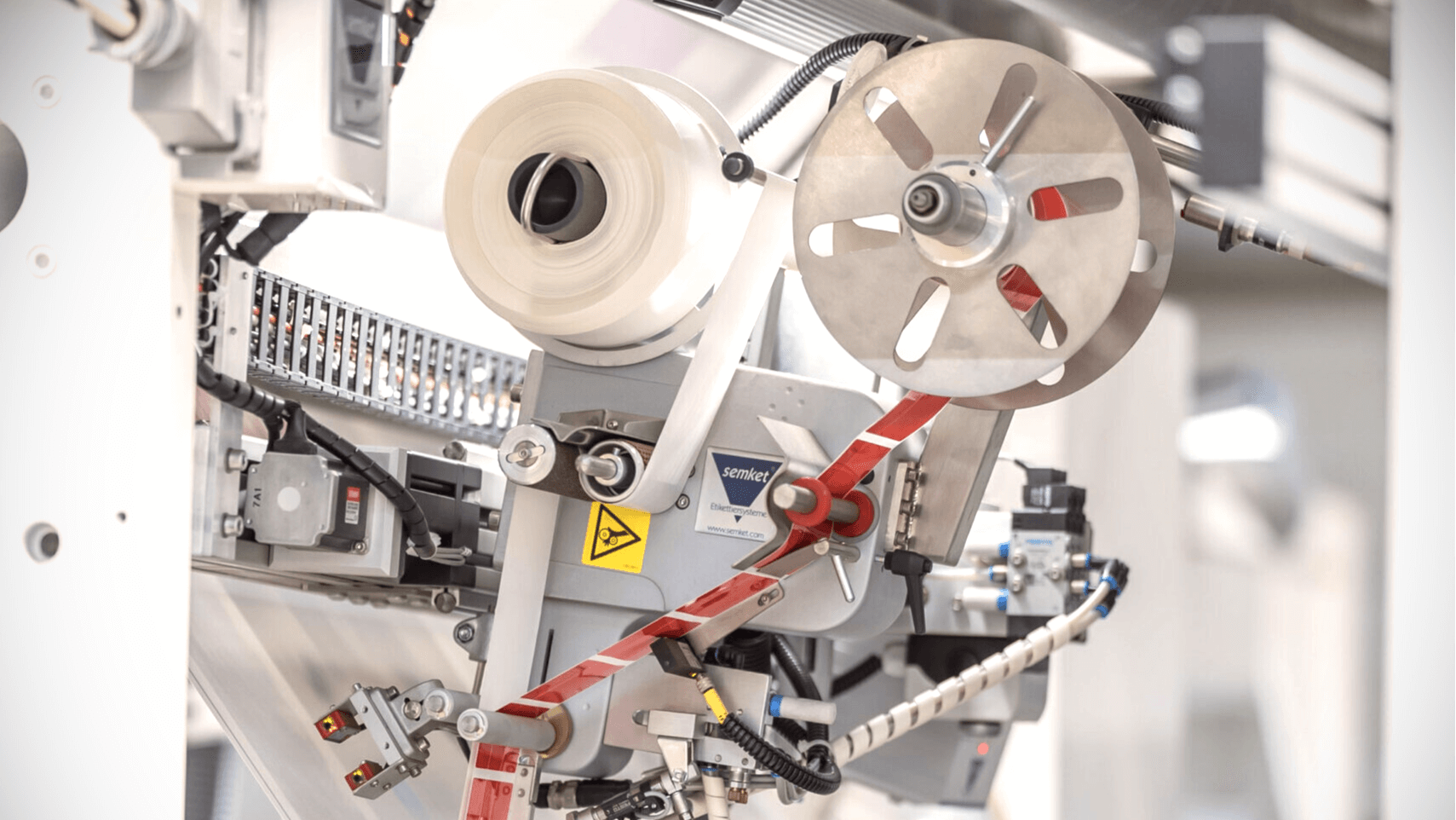

The SPM 4 labelling system ensures fully automatic labelling in industrial applications. Accurate positioning and precise

Label application round off the advantages of this reliable system.

SPM 4 offers:

Features of the SPM 4 defect marking at a glance:

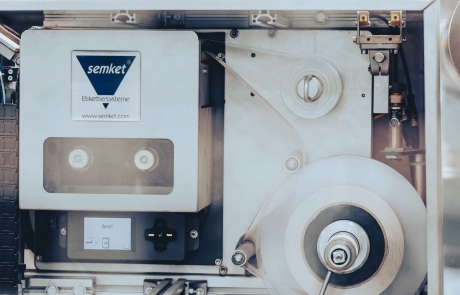

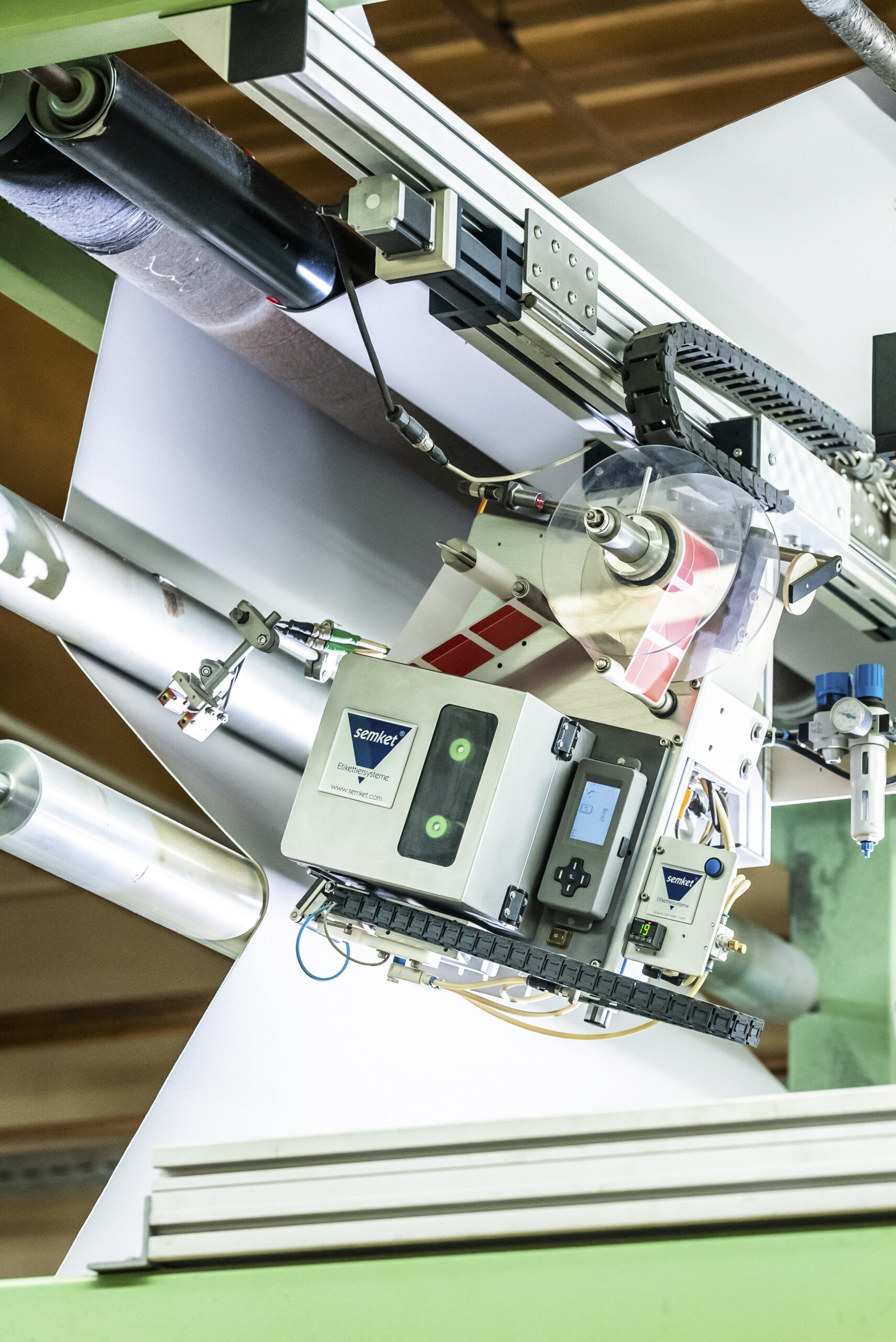

The SAB labeling system is used for the precise application of labels with automatic positioning – durable, reliable and always accurate. High-quality defect marking takes place within the framework of a solid mechanical design – controlled by semket software adapted to your needs.

Features of the SAB error marking at a glance:

The SAB labeling system is used for the precise application of labels with automatic positioning – durable, reliable and always accurate. High-quality defect marking takes place within the framework of a solid mechanical design – controlled by semket software adapted to your needs.

Features of the SAB error marking at a glance:

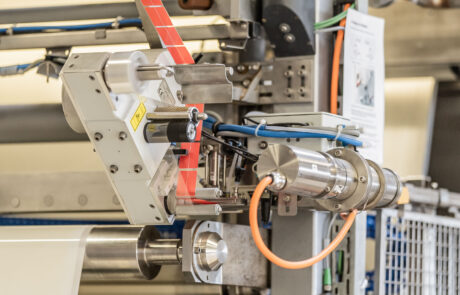

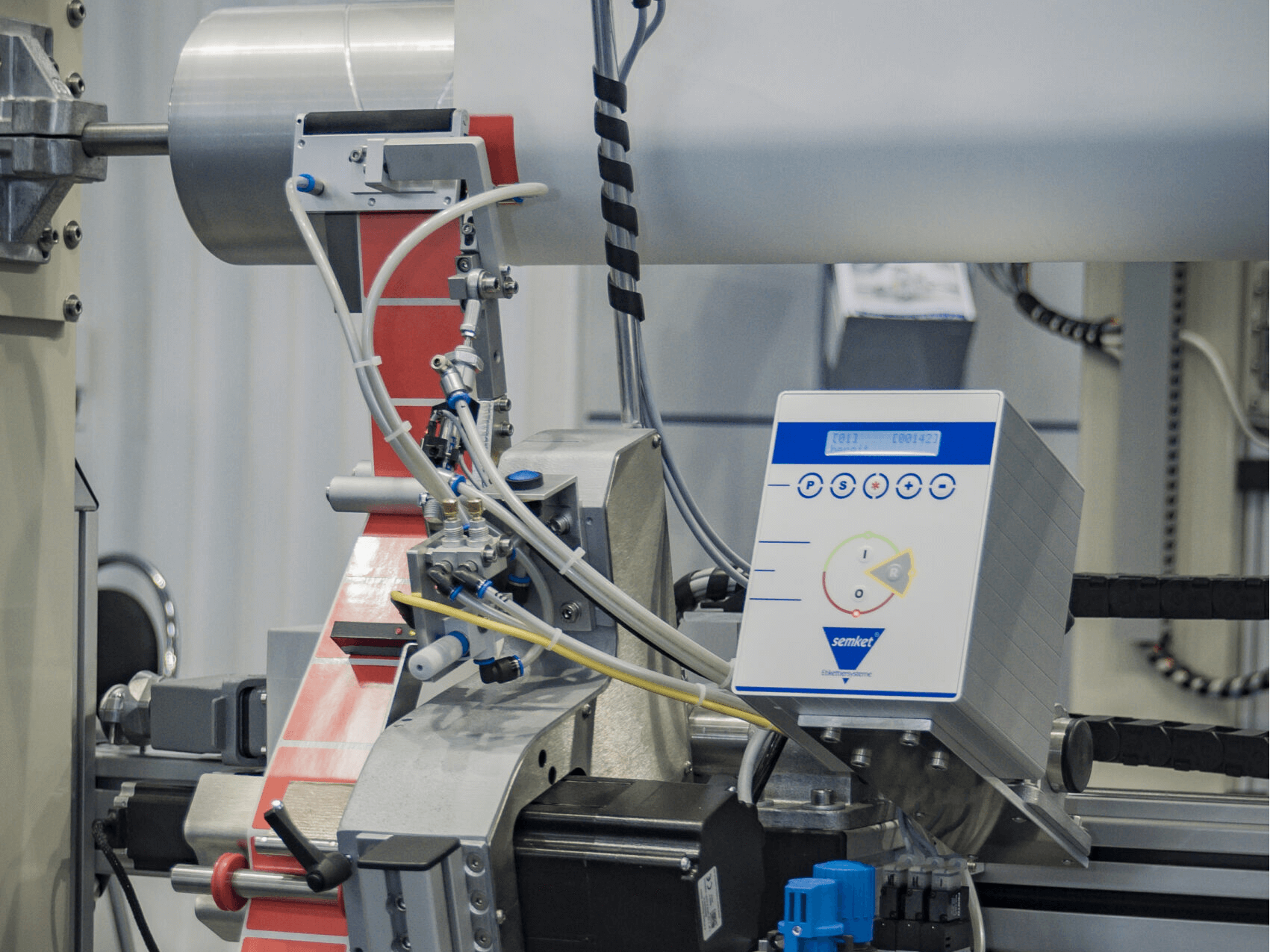

As a universal labelling machine, the AG 14 error marking system operates reliably, economically and flexibly.

The solution is adapted exactly to your needs.

Features of the industrial AG 14 labelling system at a glance:

semket Etikettiersysteme GmbH

Tirolerstrasse 9, 3105 St. Pölten-Radlberg

Tel: +43 2742 470 470

FAX: +43 2742 470 47 90

e-mail: office@semket.com

Web: www.semket.com

Monday till Thursday:

8:00 – 12:00

Monday till Thursday:

13.00 – 16:00

Friday:

8:00 – 12:00

Saturday, Sunday and holidays:

Closed